The measurement and normalisation of dielectric dissipation factor for diagnostics of transformer insulation

Abstract This article describes additional features of the method of Dielectric Dissipation Factor (DDF)/Tangent Delta (tgδ) measurement for a more accurate diagnosis of the condition...

by Anatoly Shkolnik

Abstract

This article describes additional features of the method of Dielectric Dissipation Factor (DDF)/Tangent Delta (tgδ) measurement for a more accurate diagnosis of the condition of the transformer solid insulation. The proposed method is based on determining the DDF weight of solid insulation and oil in the measured value of DDF for the proper insulation zone of the transformer. The article proposes normalisation of DDF values according to the rated voltage of the transformer, and the analysis of the impact of design combining insulation and its condition on recalculation of DDF measurement results at a given temperature to the base temperature.

Keywords: transformer, dielectric dissipation factor (DDF), transformer insulation

Introduction

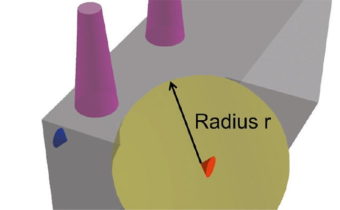

The Dielectric Dissipation Factor (DDF) is known as the loss factor or tangent delta of the insulation. The combined transformer insulation includes oil-impregnated cellulose materials and oil. When one of the insulating zones of the transformer is placed between two electrodes (either between windings or between the winding and a metal construction such as the core, frame or tank) under applied voltage, leakage current will flow. This current flowing through the insulation has two components – a reactive and an active one. The angle between vectors of these currents, which is close to 90°, and the ratio between them is equal to tangent of the angle (tgδ) between the vector of the reactive current and the vector of the full leakage current.

The Dielectric Dissipation Factor (DDF)/Tangent Delta (tgδ) measurement of the transformer insulation is a traditional method used for estimation of the transformer insulation condition. The differences between measured DDF values for different transformer insulation zones depend on the construction, condition and temperature of the insulation. Insulation zones are composed of transformer oil and oil impregnated cellulose materials (paper, pressboard, wood and laminated wood) (OIP). Dielectric parameters of oil sample and insulation zones, e.g. high to low voltage windings or windings to the core and tank, can be measured but the parameters of the solid material can only be estimated using special methods. The design of the insulation zones varies for different transformers, and the contribution of the DDF value for each elementary insulation material to the DDF value of the insulation zone is individual for each transformer type. Therefore, using uniform acceptance DDF values for all insulating zones and a uniform correction factor for temperature recalculation is not correct. This article proposes a method of measurement and calculation of DDF and capacitance for different insulating zones of transformers. The interpretation of these results promotes a better diagnostics and estimation of the condition of transformer insulation during the following stages: at the acceptance test of new transformers and after repair, at the test after change or reclaiming of oil, at the test after drying process, during the periodical test.