Accurate determination of transformer insulation risk and remaining life

Moisture and temperature are the biggest drivers of irreversible transformer aging

by Richard Harris

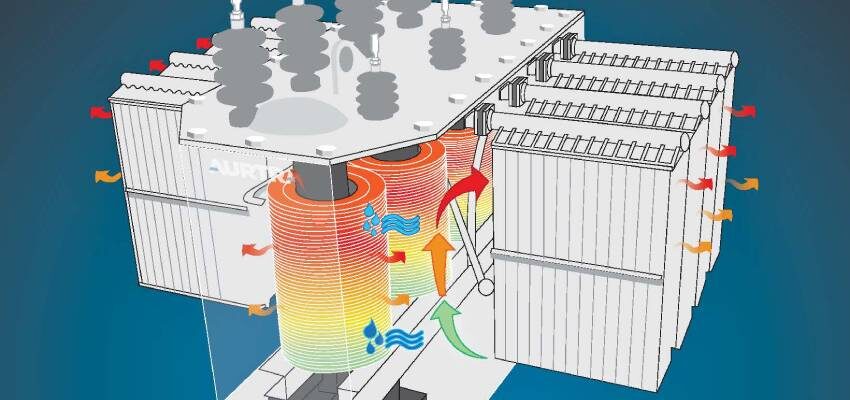

Introduction to insulation breakdown

Moisture and temperature are the biggest drivers of irreversible transformer aging. The critical issue is that temperature causes polymer chains in the paper to break down. At start-of-life, the paper insulation within a transformer consists of long intertwined cellulose chains, which make it structurally strong, tough and durable to resist mechanical and electrical stresses.

Over time, chemical breakdown of these chains ultimately makes the paper mechanically weak, brittle and unable to withstand normal operating stress. This stress is caused mainly by heating cycles and transient electrical forces. Cracks and breaks become more probable and the risk of electrical breakdown and structural instability increases. Eventually, the structural strength of the paper and pressboard cannot withstand the mechanical stress, and the electrical insulation role it plays is compromised, resulting in a failure of the transformer. Moisture exacerbates this aging effect. For example, perfectly dry Kraft paper (< 0.5 % moisture and medium oxygen [1]) operated at 80 degrees will last > 20 years before it is critically damaged. Add 2 % moisture and the usable life left falls to 3 years. Add 4 % moisture and it falls to just over one year.

Moisture and temperature are the biggest drivers of irreversible transformer aging

Measuring temperature and moisture

Measuring the temperature of a transformer is relatively easy, in comparison with measuring the water content of the paper. For example, sensors can be located throughout the transformer winding. Alternatively, close estimates can be made from measuring the top oil temperature as it exits the core or enters the radiator.

On the other hand, assessing the water content is much more difficult. Precision requires sampling the paper, which is not possible without removing the transformer from service. Using the measurements from the oil is far more difficult. Water Content of Oil (WCO) vs Water Content of Paper (WCP) relationships have been developed and refined for decades by some of the best practitioners and researchers. Unfortunately, these methods remain prone to serious error for fundamental reasons discussed below.

Log in or subscribe to read the whole article.